Sigma Air Conditioning System, Parts and Maintenance Services

Lyons Partner with Sigma AC to Become the Largest Distributor Wholesaler in Australia

SIGMA Air Conditioning is a world leader for the design and manufacture specialised air conditioning equipment suitable for the mining, construction and transportation industries where high ambient temperatures, severe vibration, dense particulate and corrosive environments prevail.

Sigma innovative and uniquely designed equipment has become the industry benchmark for automotive heavy duty air-conditioning systems. A leading global company, Sigma have developed a comprehensive range of air conditioning and filtration equipment built to withstand and perform in Australia’s harsh environment.

Lyons in conjunction with SIGMA provides a a holistic approach with its products and provides tailored system solutions that deliver true value to our customers.

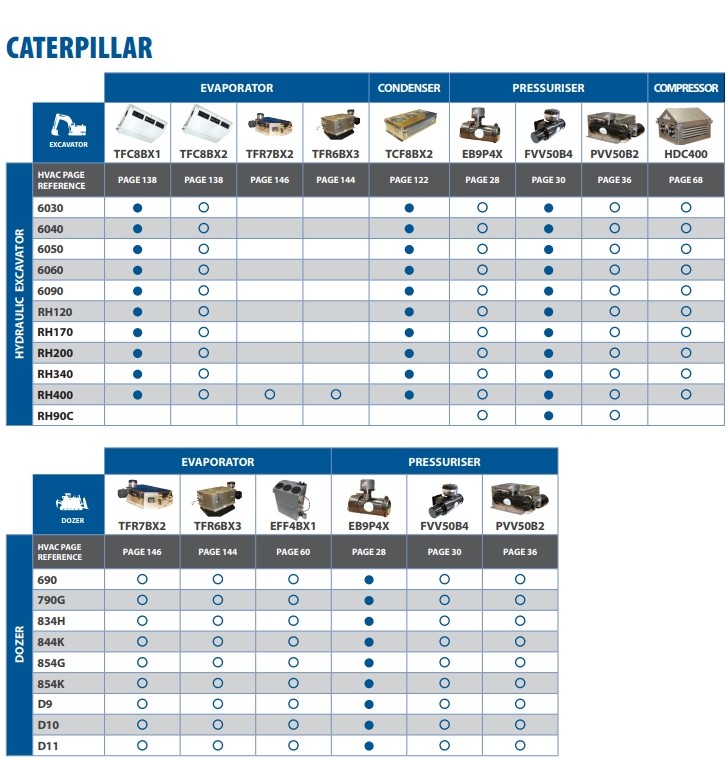

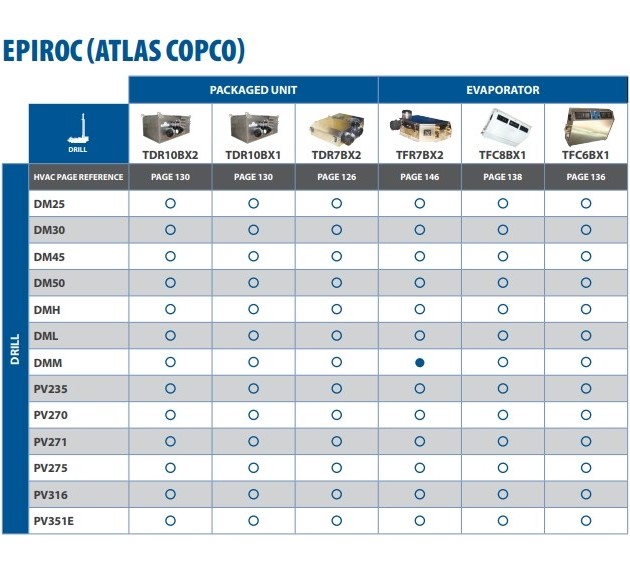

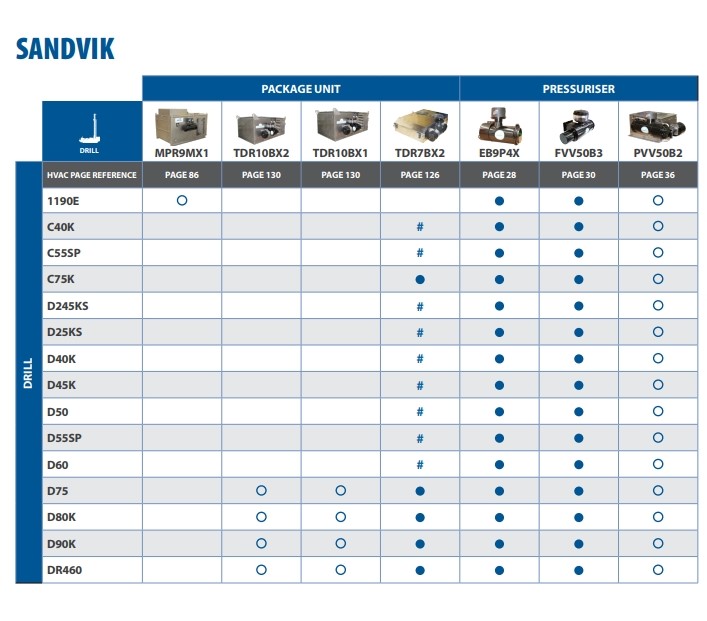

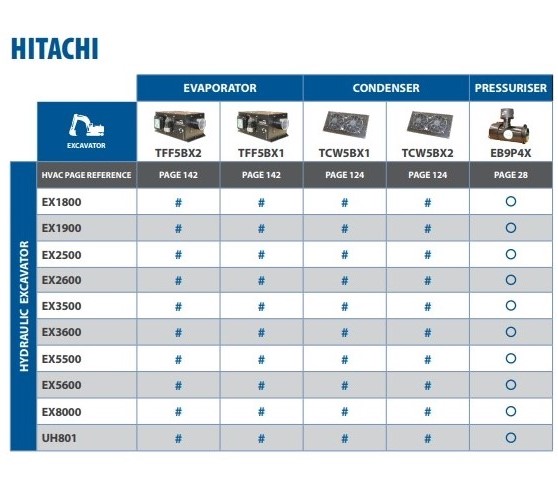

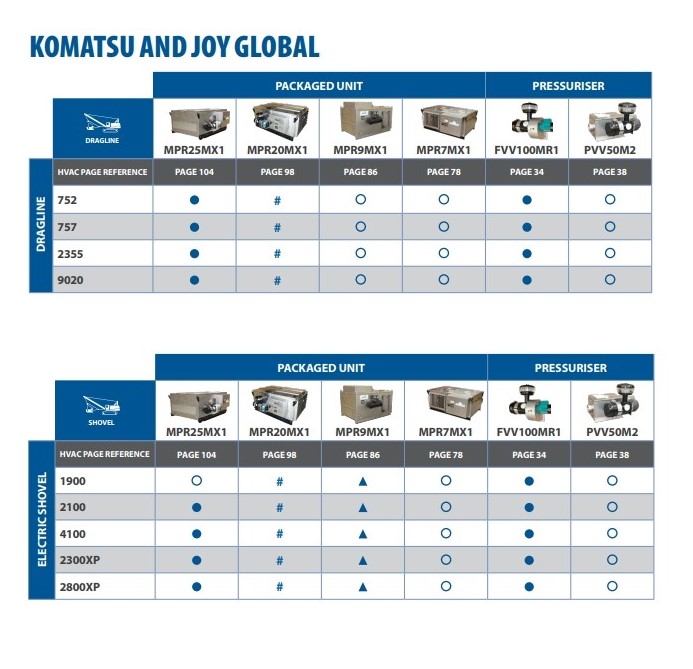

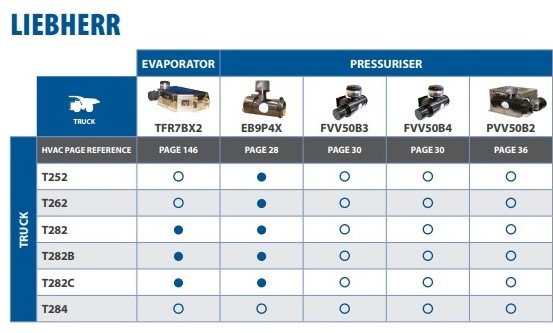

Sigma Air-Conditioner System Matrix

A large range of off-the-shelf or custom heavy vehicle air-conditioning Systems to suit excavators, bulldozers, cranes, drills, loaders, graders and any other equipment with or without operator.

AC Spare Parts

Lyons provides direction and support to ensure you keep trucking to minimise downtime and operator efficiency. We have a large warehouse of parts and accessories suitable for Sigma systems

Zero Failure is at the core of everything we do from the engineering design, manufacturing, service, maintenance and overhauls. This ensures maximum up time, increased productivity and Customer Confidence. Special Vehicles are built for specific tasks and conditions, every part must be tested, trusted and maintained to perform to the highest standards in the toughest environments.

Ongoing service, maintenance and smart thinking upgrades are all part of the ongoing life cycle of achieving Zero Failure and include:

- Genuine OEM Spare Parts: Manufactured to the original standards and specifications set by SIGMA.

- HVAC Service Kits: Tailored spare part kits to support services. Designed to be task specific and efficient. Maintenance Programs Preventative maintenance programs built to ensure maximum efficiency and up time.

- Exchange and Overhaul: Timely solutions for longer life and lower costs.

- Condition Based Maintenance: Engineering efficiency and zero failure.

Sigma Filtration Pressurisers

Developed for environments containing gaseous or fibrous contaminants, the filter/pressuriser systems contain four (4) stages of filtration. The first two (2) stages of filtration efficiently remove sub-micron particulate from outside air, following by stage 3 customised filtration media to remove the specific gaseous or fibrous contaminant and finally stage 4 HEPA filtration.